🧩 Visual Frameworks & Illustrations

🌟 Project Overview

As part of a strategic collaboration with Aeroflot, I led the implementation of a cutting-edge Corporate Production Management Automation system, designed to optimize the airline’s operational, managerial, and reporting processes. This initiative, executed by BS&S–Teleform, focused on overcoming legacy challenges and streamlining Aeroflot’s critical business processes, significantly boosting operational efficiency and managerial transparency.

🚩 Key Objectives & Challenges

Legacy System Replacement: Modernize outdated legacy systems based on obsolete technologies (e.g., FoxPro), addressing performance, support, and documentation availability issues.

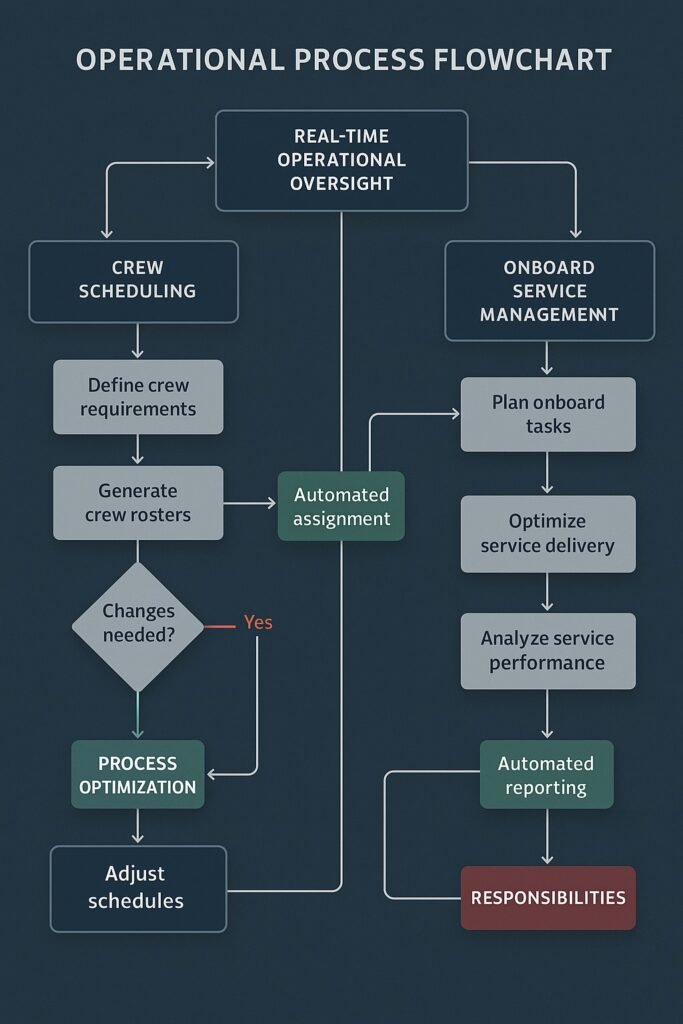

Comprehensive Process Automation: Automate complex processes related to crew planning, onboard service management, and commercial reporting systems.

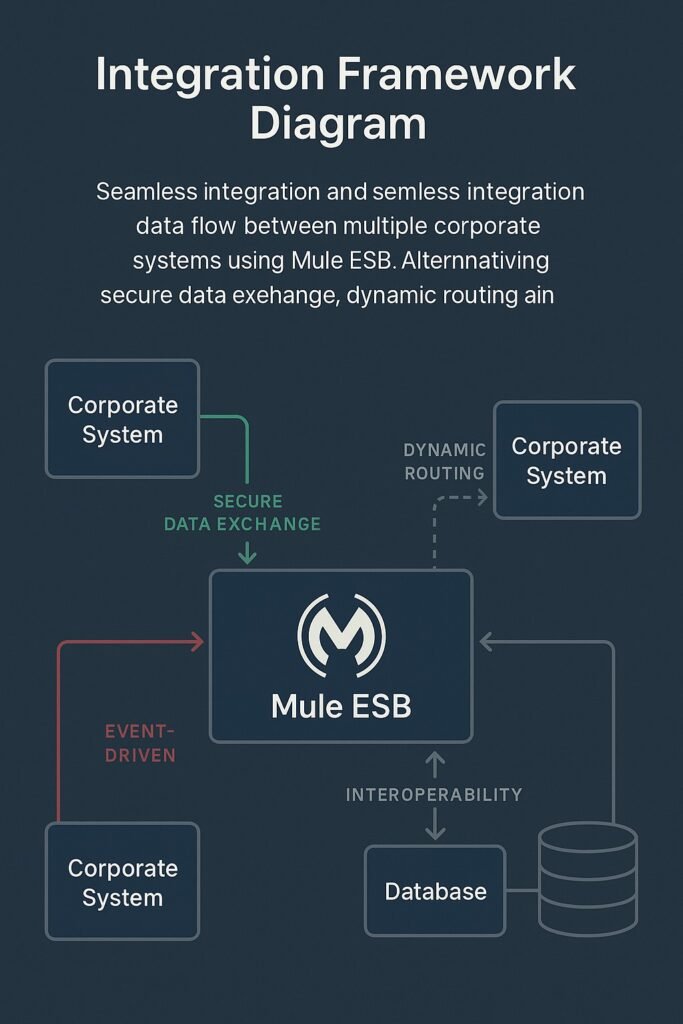

Integration Complexity: Integrate seamlessly with Aeroflot’s existing IT infrastructure, ensuring data accuracy, real-time processing, and comprehensive reporting capabilities.

Strategic Decision Support: Implement robust analytical reporting systems to enable real-time decision-making and enhance strategic planning.

🔍 Technological Approach & Innovations

Advanced Integration Framework (Mule ESB): Leveraged Mule ESB to create a robust integration infrastructure, significantly reducing data processing errors and enhancing interoperability among diverse corporate systems.

Tailored Solution Selection: Conducted a detailed comparative analysis of market solutions, customized in-house developments, and hybrid solutions to determine the most effective and flexible system architecture for Aeroflot’s operational needs.

Comprehensive Reporting Systems: Developed an innovative, flexible reporting system enabling Aeroflot’s commercial and operational units to generate real-time, customizable reports, providing deeper insights into operational performance.

Systematic Requirements and Technical Analysis: Conducted extensive requirement gathering, systematization, and detailed technical analysis to form a robust basis for automated system development.

📊 Results & Measurable Outcomes

Operational Efficiency: Achieved substantial improvements in the automation of crew management and onboard services, reducing operational times by approximately 25% and significantly minimizing manual processes.

Data Accuracy & Real-Time Reporting: Enhanced data reliability and real-time reporting capabilities, providing accurate, timely information to support managerial decisions and strategic planning.

Cost Reduction: Significantly reduced costs associated with system support and maintenance by migrating from outdated legacy systems, achieving savings of up to 30% on IT support and operational management.

Improved Decision-Making: Enabled robust, data-driven decision-making through advanced analytical capabilities, increasing responsiveness and transparency across Aeroflot’s corporate structure.

🎯 My Leadership Role & Contributions

Directed strategic analysis, solution selection, technical architecture, and comprehensive implementation phases of the project.

Facilitated extensive collaboration with stakeholders, ensuring alignment with Aeroflot’s business goals, and managed project timelines and quality standards rigorously.

Conducted and oversaw comprehensive business process consulting to optimize Aeroflot’s production activities, aligning technological solutions with strategic organizational objectives.

🚀 Strategic Importance Conclusion

The successful automation of Aeroflot’s Corporate Production Management has significantly resolved existing operational inefficiencies, thereby enhancing the airline’s operational efficiency and strategically positioning it for ongoing innovation and competitiveness in the global aviation industry. This transformative initiative enabled Aeroflot to leverage state-of-the-art IT solutions, delivering a superior customer experience, and fostering agile management practices.